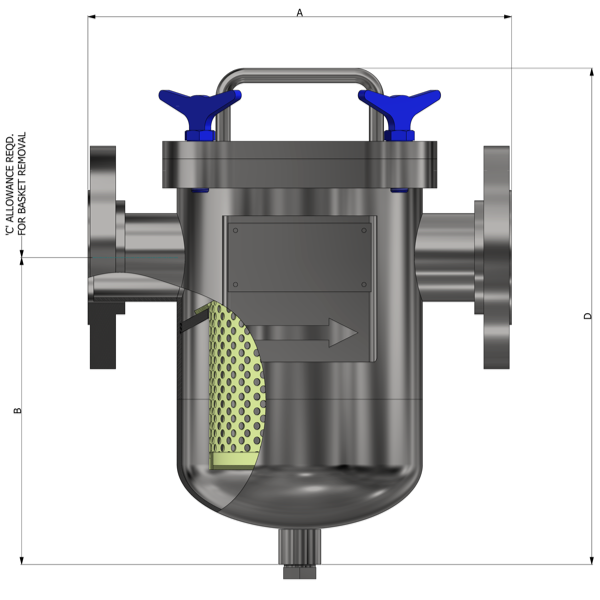

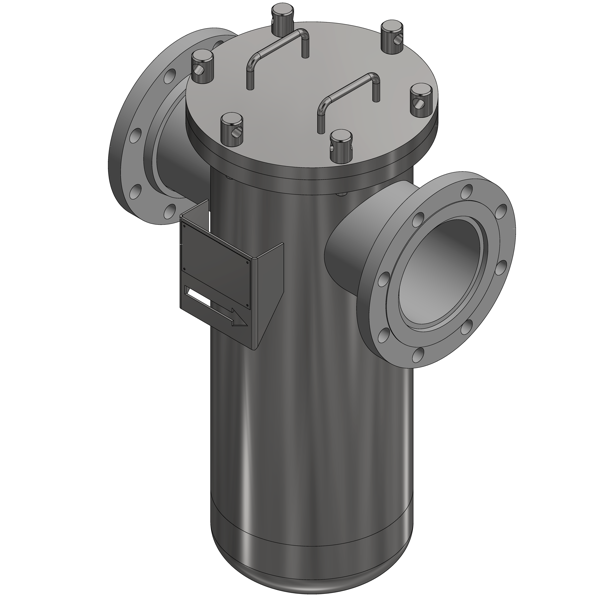

GTS Series Basket Strainer

The Ulbrec GTS Series of strainers are known for their high technical Integrity, ease of use and maintainability. Our vast range of flexible options, rapid delivery, verified DP performance make the GT series a superior solution entirely focused on delivering value to end users. An economical standard production strainer that can also be engineered to special and highly technical requirements and delivered on short lead time with full technical and logistic support.

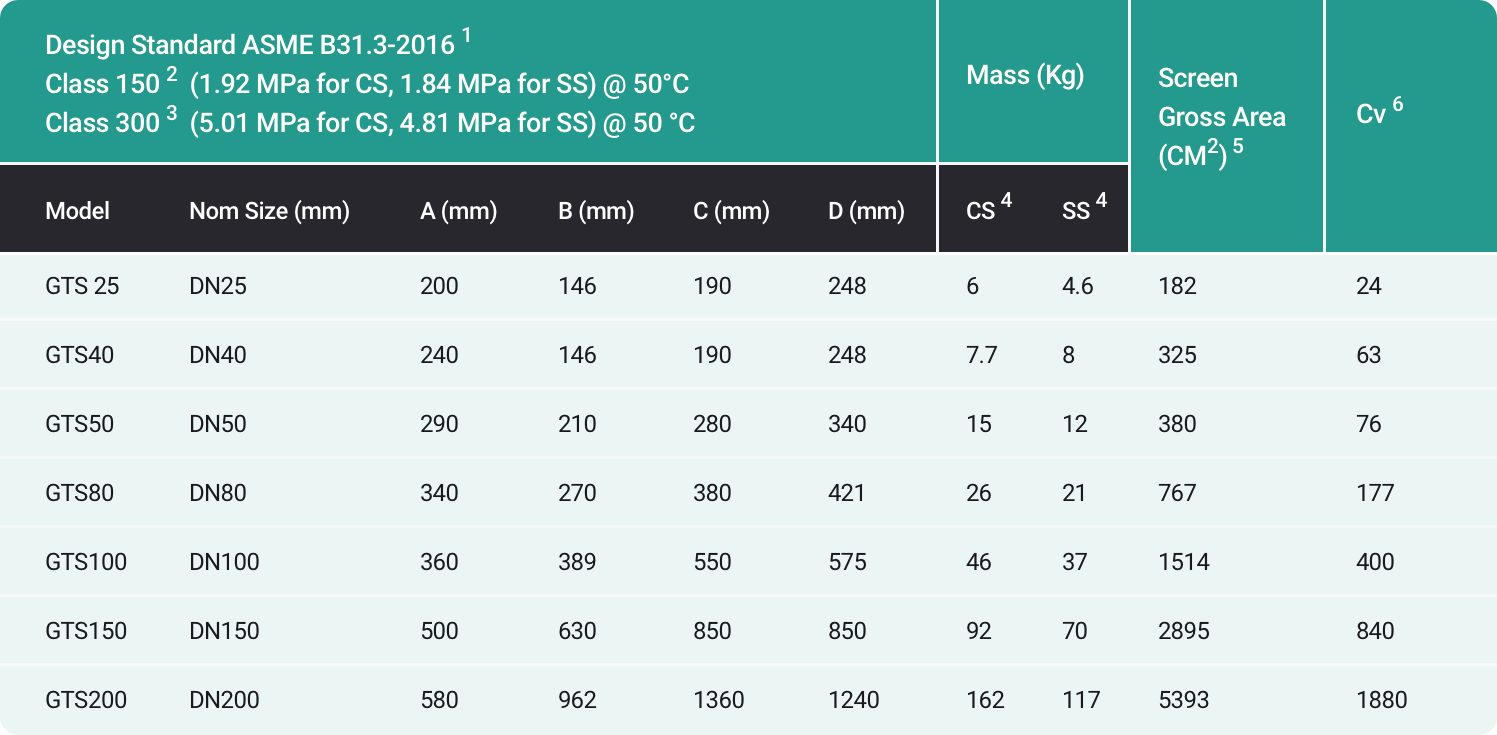

Model Specs

1. optional AS4041, AS1210 & ASME VIII Div 1 2. when fitted with ASME B16.5 class 150 flanges 3. when fitted with ASME B16.5 class 300 flanges 4. CS - carbon steel; SS – stainless steel 5. increased screen area available on short lead time 6. clean screen condition with 3mm aperture. Consult Ulbrec for DP with different process fluids, filtration levels and basket fouling degrees * Optional pressure ratings up to class 1500 subject to dimensional variations * Circular process bolt closure is standard for GTS150 and 200

Options

- Standard GTS-SS off the shelf in ASTM A312 T316/316L and ASTM A403-WP-316/316L

- Standard GTS-CS off the shelf in ASTM A53/API 5L GrB and ASTM A234-WPB

- Short lead times for special materials using ASME IX / AS 3992 qualified weld procedures for low temperature carbon steels, NACE compliance, duplex stainless steels, super austenitic steel etc

- Standard low pressure drop surface filtration screens and a vast range of Engineered to Order solutions

- Exotic materials including Inconel, Incoloy, Titanium, Monel, Duplex and Super Duplex stainless steels

- Specified high burst-collapse strength

- Square weave, hollander weave and mechanically perforated designs in single and multi-layer construction, Sintered mesh, "wedgewire"

- World-leading, extreme performance laser screens with tapered apertures, high resistance to blockage, outstanding cleaning performance and structural strength.

- ANSI RF flanged - SORF (standard) WNRF

- ANSI RTJ

- FF table flanges

- PN flanges

- Screwed, NPT, BSP, BSM etc

- Sanitary tri-clamp

- Butt weld

- Ulbrec Veelok Quick Clamp

- Wing bolt o-ring closure (standard for GTS25 to 100)): 316 SS wing bolt with petrochem grade Xylan 1424 series coating & nitrile o-ring

- Process bolt option (standard for GTS150 & 200) for operation using a round bar, podger or screwdriver shank

- ANSI RF flanged option (SORF or WNRF) with flat or Spiral Wound Gasket - Ulbrec Series 350

- Ulbrec fast opening swing bolt closure option - Ulbrec Series 250 with full compliance to ASME BPV VIII Div 1 and Div 2

- Quick Opening Closures in toothed and band types - ASME BPV VIII Div 1 compliant

- Ulbrec Veelok Quick Clamp

- Viton, Kalrez, PTFE encapsulated etc o-rings for heat and chemical resistance

- Metal o-rings in very high resistance materials for high pressure / temperature applications

- Legs, mounting lugs, base ring / tabs or skirts, verified for combined loadings

- Foundation loads

- Vent, drain